What is Thermal Deburring?

Thermal deburring is a process aimed at uniformly eliminating burrs on components that come from specific machining operations (milling, CNC, die casting etc.) but maintains the original geometries. The process takes advantage of a chemical-physical principle, generating heat by the ignition of an appropriate combustible mixture, just as in the case of heat engines.

The energy obtained catalyzes the excess oxygen present in the original combustion mixture to instantly oxidize and so eliminate burrs, slags and unwanted material present on the edges, within the cavities and on the more or less hidden surfaces of the parts undergoing this treatment.

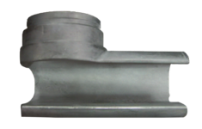

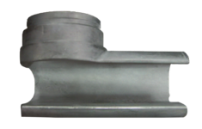

Before

After

Offered Services

ST's know-how is constantly at the service of the client throughout the various phases of the client's approach to the Thermal Deburring process; from start to finish.

• Phase 1

Accurate analysis of the details, geometries and dimensions of the burrs to be removed.

• Phase 2

Conductance of non-destructive free-of-charge tests on the sample parts, with the goal of determining optimal processing and manufacturing standards, that meet the client's ideal quality requirements, and pricing.

• Phase 3

Once the parameters are agreed upon by us and the client, the repeatability and homogenous results of SGM® machines, mixed with ST’s 40+ year experience, are guaranteed to leave the client satisfied and carefree.